3.1.6.18. ASDConcrete3D Material

- nDMaterial ASDConcrete3D $tag $E $v <-rho $rho>

- <-fc $fc> <-ft $ft>

- <-Te $Te -Ts $Ts <-Td $Td>>

- <-Ce $Ce -Cs $Cs <-Cd $Cd>>

- <-implex> <-implexControl $implexErrorTolerance $implexTimeReductionLimit> <-implexAlpha $alpha>

- <-crackPlanes $nct $ncc $smoothingAngle>

- <-eta $eta> <-tangent> <-autoRegularization $lch_ref> <-Kc $Kc>

- <-cdf $cdf>

Argument |

Type |

Description |

|---|---|---|

$tag |

integer |

Unique tag identifying this material. |

$E $v |

2 float |

Mandatory. Young’s modulus and Poisson’s ratio. |

-rho $rho |

string + float |

Optional. -rho: A keyword that precedes the float. $rho: The mass density. |

-fc $fc |

string + float |

Optional. -fc: A keyword that precedes the float. $fc: The concrete compressive strength. |

-ft $ft |

string + float |

Optional. -ft: A keyword that precedes the float. $ft: The concrete tension (rupture) strength. |

-Te $Te |

string + list |

Optional. -Te: A keyword that precedes the list. $Te: A list of total-strain values for the tensile hardening-softening law. If not specified, $Te will be computed automatically from $fc and $ft. If specified, $Te will override $fc and $ft. |

-Ts $Ts |

string + list |

Optional. -Ts: A keyword that precedes the list. $Ts: A list of stress values for the tensile hardening-softening law. If not specified, $Ts will be computed automatically from $fc and $ft. If specified, $Ts will override $fc and $ft. |

-Td $Td |

string + list |

Optional. -Td: A keyword that precedes the list. $Td: A list of damage values for the tensile hardening-softening law. If not defined, no stiffness degradation will be considered. If not specified, $Td will be computed automatically from $fc and $ft. If specified, $Td will override $fc and $ft. |

-Ce $Ce |

string + list |

Optional. -Ce: A keyword that precedes the list. $Ce: A list of total-strain values for the compressive hardening-softening law. If not specified, $Ce will be computed automatically from $fc and $ft. If specified, $Ce will override $fc and $ft. |

-Cs $Cs |

string + list |

Optional. -Cs: A keyword that precedes the list. $Cs: A list of stress values for the compressive hardening-softening law. If not specified, $Cs will be computed automatically from $fc and $ft. If specified, $Cs will override $fc and $ft. |

-Cd $Cd |

string + list |

Optional. -Cd: A keyword that precedes the list. $Cd: A list of damage values for the compressive hardening-softening law. If not defined, no stiffness degradation will be considered. If not specified, $Cd will be computed automatically from $fc and $ft. If specified, $Cd will override $fc and $ft. |

-implex |

string |

Optional. If defined, the IMPL-EX integration will be used, otherwise the standard implicit integration will be used (default). |

-implexControl $implexErrorTolerance $implexTimeReductionLimit |

string + 2 float |

Optional. -implexControl: Activates the control of the IMPL-EX error. implexErrorTolerance: Relative error tolerance. implexTimeReductionLimit: Minimum allowed relative reduction of the time-step. If the error introduced by the IMPL-EX algorithm is larger than implexErrorTolerance , the material will fail during the computation. The user can therfore use an adaptive time-step to reduce the time-step to keep the error under control. If the reduction of the time-step is smaller than implexTimeReductionLimit , the error control will be skipped. Suggested values: -implexControl 0.05 0.01. |

-implexAlpha $alpha |

string + float |

Optional. Default = 1. The \(\alpha\) coefficient for the explicit extrapolation of the internal variables in the IMPL-EX algorithm. It can range from 0 to 1. |

-crackPlanes $nct $ncc $smoothingAngle |

string + 2 integer + float |

Optional. If defined, it activates the anisotropy of internal variables. Tensile internal variables are stored on crack-planes that are equally spaced every \(90/nc_t\) degrees. Compressive internal variables are stored on crack-planes that are equally spaced every \(90/nc_c\) degrees. The active crack-plane is chosen based on the current principal stress directions. smoothingAngle: Angle in degrees used to smooth the internal variables on crack-planes around the active crack-plane. Suggested values: -crackPlanes 4 4 45.0 |

-eta $eta |

string + float |

Optional. If defined, the rate-dependent model is used (By default the model is rate-independent). -eta: Activates the rate-dependent model. eta: The viscosity parameter \(\eta\), representing the relaxation time of the viscoplastic system. |

-tangent |

string |

Optional. If defined, the tangent constitutive matrix is used. By default, the secant stiffness is used. |

-autoRegularization $lch_ref |

string + float |

Optional. If defined, and if the tensile and/or the compressive hardening-softening law has strain-softening, the area under the hardening-softening law is assumed to be a real fracture energy (\(G_f\) with dimension = \(F/L\)), and the specific fracture energy \(g_f\) (with dimension = \(F/L^2\)) is automatically computed as \(g_f=G_f/l_{ch}\), where \(l_{ch}\) is the characteristic length of the Finite Element. In this case $lch_ref is 1. If, instead, the area is a specific fracture energy (\(g_{f,ref}\) with dimension = \(F/L^2\)), $lch_ref should be set equal to the experimental size used to obtain the strain from the displacement jump. In this case, the regularization will be performed as \(g_f=G_f/l_{ch} = g_{f,ref}*l_{ch,ref}/l_{ch}\) |

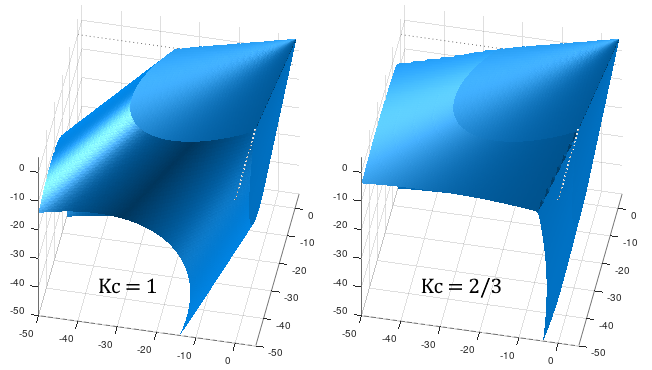

-Kc $Kc |

string + float |

Optional. -Kc: A keyword that precedes the float. $Kc: A coefficient that defines the shape of the failure surface in triaxial compression. It must be \(1/2 < K_c <= 1\), default = \(2/3\). The lower \(K_c\), the stronger is the material in triaxial compression:

Fig. 3.1.6.2 Effect of \(K_c\) on the triaxial-compression part of the failure surface. |

-cdf $cdf |

string + float |

Optional (default = 0). The Cross-Damage-Factor (cdf) control the dilatancy of the material. cdf should be >= 0. The larger cdf, the smaller the dilatancy. 0 is the optimal value for concrete. |

3.1.6.18.1. Theory

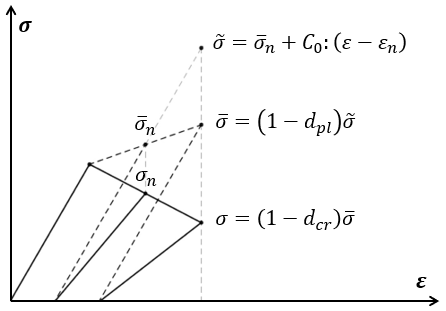

Fig. 3.1.6.3 A schematic representation of the elastic predictor followed by the plastic and damage correctors in a representative uniaxial case.

3.1.6.18.2. Usage Notes

Responses

All responses available for the nDMaterial object: stress (or stresses), strain (or strains), tangent (or Tangent), TempAndElong.

damage or Damage: 2 components (\(d^+\), \(d^-\)). The cracking damage variables. If option -crackPlanes is used, it gives the maximum values among all crack-planes.

damage -avg or Damage -avg: 2 components (\(d^+\), \(d^-\)). Same as above. If option -crackPlanes is used, it gives the average values of the crack-planes.

equivalentPlasticStrain or EquivalentPlasticStrain: 2 components (\(x_{pl}^+\), \(x_{pl}^-\)). The equivalent plastic strains. If option -crackPlanes is used, it gives the maximum values among all crack-planes.

equivalentPlasticStrain -avg or EquivalentPlasticStrain -avg: 2 components (\(x_{pl}^+\), \(x_{pl}^-\)). Same as above. If option -crackPlanes is used, it gives the average values of the crack-planes.

equivalentTotalStrain or EquivalentTotalStrain: 2 components (\(x^+\), \(x^-\)). The equivalent total strains. If option -crackPlanes is used, it gives the maximum values among all crack-planes.

equivalentTotalStrain -avg or EquivalentTotalStrain -avg: 2 components (\(x^+\), \(x^-\)). Same as above. If option -crackPlanes is used, it gives the average values of the crack-planes.

cw or crackWidth or CrackWidth: 1 component (\(cw\)). The equivalent tensile total strain minus the equivalent strain at the onset of crack, times the characteristic length of the parent element. If option -crackPlanes is used, it gives the maximum value among all crack-planes.

cw -avg or crackWidth -avg or CrackWidth -avg: 1 component (\(cw\)). Same as above. If option -crackPlanes is used, it gives the average value of the crack-planes.

crackInfo $Nx $Ny $Nz or CrackInfo $Nx $Ny $Nz: 2 components (\(ID\), \(X\)). Gives the 0-based index (ID) and the tensile equivalent total strain (X) of the crack-plane with the normal vector closest to (Nx, Ny, Nz).

crushInfo $Nx $Ny $Nz or CrushInfo $Nx $Ny $Nz: 2 components (\(ID\), \(X\)). Same as above, but for the compressive response.

Example 1 - Drawing the Damage Surface

A Python example to draw the damage surface in the plane-stress case: ASDConcrete3D_Ex_Surface.py

Example 2 - Understanding the Hardening/Softening Laws

ASDConcrete3D_MakeLaws.pyASDConcrete3D_Ex_CyclicUniaxialTension.py and ASDConcrete3D_Ex_CyclicUniaxialCompression.py3.1.6.18.3. References

Petracca, M., Camata, G., Spacone, E., & Pelà, L. (2022). “Efficient Constitutive Model for Continuous Micro-Modeling of Masonry Structures” International Journal of Architectural Heritage, 1-13 (Link to article)

Oliver, J., Huespe, A. E., & Cante, J. C. (2008). “An implicit/explicit integration scheme to increase computability of non-linear material and contact/friction problems” Computer Methods in Applied Mechanics and Engineering, 197(21-24), 1865-1889 (Link to article)

Code Developed by: Massimo Petracca at ASDEA Software, Italy.