3.1.6.4. Drucker Prager Material

Code Developed by: Peter Mackenzie-Helnwein and Pedro Arduino at U.Washington.

This command is used to construct an multi dimensional material object that has a Drucker-Prager yield criterion.

- nDMaterial DruckerPrager $matTag $k $G $sigmaY $rho $rhoBar $Kinf $Ko $delta1 $delta2 $H $theta $density <$atmPressure>

Argument |

Type |

Description |

|---|---|---|

$matTag |

float |

integer tag identifying material |

$k |

float |

bulk modulus |

$G |

float |

shear modulus |

$sigmaY |

float |

yield stress |

$rho |

float |

frictional strength parameter |

$rhoBar |

float |

controls evolution of plastic volume change: 0 ≤ $rhoBar ≤ $rho |

$Kinf |

float |

nonlinear isotropic strain hardening parameter: $Kinf ≥ 0 |

$Ko |

float |

nonlinear isotropic strain hardening parameter: $Ko ≥ 0 |

$delta1 |

float |

nonlinear isotropic strain hardening parameter: $delta1 ≥ 0 |

$delta2 |

float |

tension softening parameter: $delta2 ≥ 0 |

$H |

float |

linear strain hardening parameter: $H ≥ 0 |

$theta |

float |

controls relative proportions of isotropic and kinematic hardening: 0 ≤ $theta ≤ 1 |

$density |

float |

mass density of the material |

<$atmPressure> |

float |

optional atmospheric pressure for update of elastic bulk and shear moduli (default = 101 kPa) |

Note

The material formulations for the Drucker-Prager object are “ThreeDimensional” and “PlaneStrain”

The yield condition for the Drucker-Prager model can be expressed as

in which

is the deviatoric stress tensor,

is the first invariant of the stress tensor, and the parameters .. math::rho_{}^{}</math> and .. math::sigma_Y^{}</math> are positive material constants.

The isotropic hardening stress is defined as

The kinematic hardening stress (or back-stress) is defined as

The yield condition for the tension cutoff yield surface is defined as

where

and

Further, general, information on theory for the Drucker-Prager yield criterion can be found at wikipedia here

Note

The valid queries to the Drucker-Prager material when creating an ElementRecorder are ‘strain’ and ‘stress’ (as with all nDmaterial) as well as ‘state’. The query ‘state’ records a vector of state variables during a particular analysis. The columns of this vector are as follows. (Note: If the option ‘-time’ is included in the creation of the recorder, the first column will be the time variable for each recorded point and the columns below are shifted accordingly.)

Column 1 - First invariant of the stress tensor, \(I_1 = \mathrm{tr}(\mathbf{\sigma})\). Column 2 - The following tensor norm, \(\left\| \mathbf{s} + \mathbf{q}^{kin} \right\| `, where .. math::\mathbf{s}\) is the deviatoric stress tensor and \(\mathbf{q}^{kin}\) is the back-stress tensor. Column 3 - First invariant of the plastic strain tensor, \(\mathrm{tr}(\mathbf{\varepsilon}^p) `. Column 4 - Norm of the deviatoric plastic strain tensor, :math:\)left| mathbf{e}^p right| `.

The Drucker-Prager strength parameters \(\rho ` and :math:\)sigma_Y ` can be related to the Mohr-Coulomb friction angle, \(\phi `, and cohesive intercept, :math:`c\), by evaluating the yield surfaces in a deviatoric plane as described by Chen and Saleeb (1994). By relating the two yield surfaces in triaxial compression, the following expressions are determined

Drucker, D. C. and Prager, W., “Soil mechanics and plastic analysis for limit design.” Quarterly of Applied Mathematics, vol. 10, no. 2, pp. 157–165, 1952.

Chen, W. F. and Saleeb, A. F., Constitutive Equations for Engineering Materials Volume I: Elasticity and Modeling. Elsevier Science B.V., Amsterdam, 1994.

Example

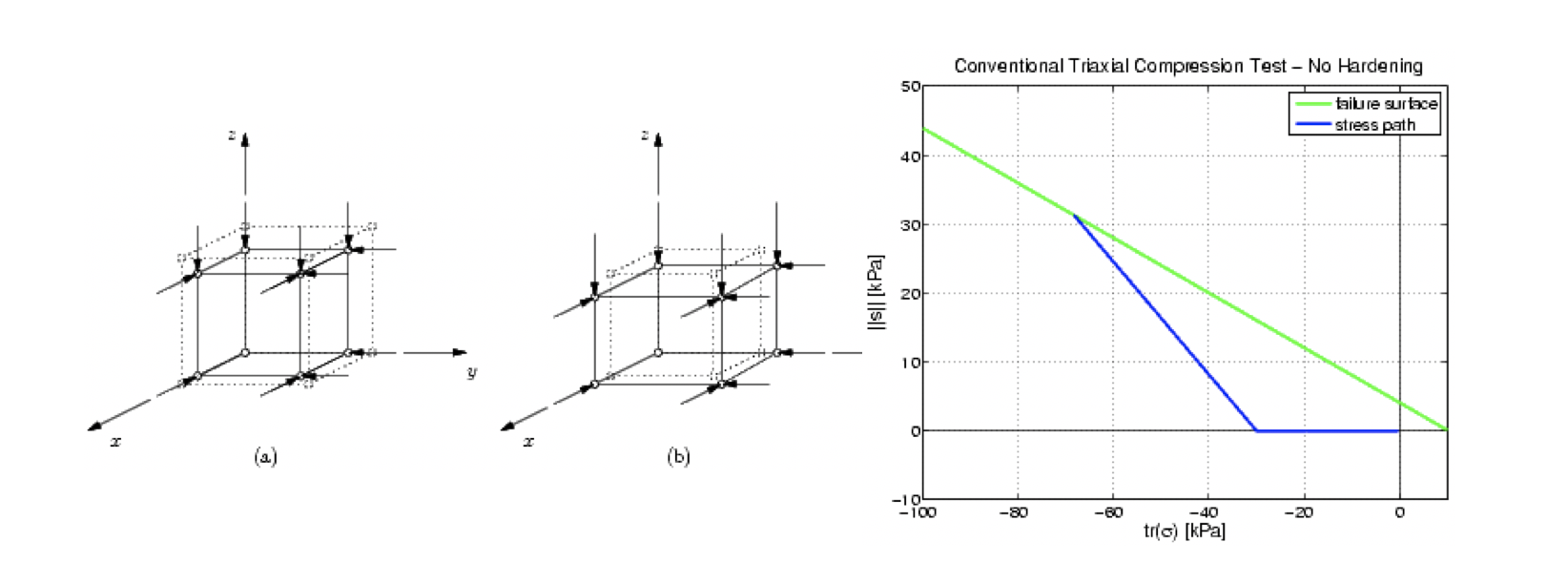

This example provides the input file and corresponding results for a confined triaxial compression (CTC) test using a single 8-node brick element and the Drucker-Prager constitutive model. A schematic representation of this test is shown below, (a) depicts the application of hydrostatic pressure, and (b) depicts the application of the deviator stress. Also shown is the stress path resulting from this test plotted on the meridian plane. As shown, the element is loaded until failure, at which point the model can no longer converge, as this is a stress-controlled analysis.

Fig. 3.1.6.1 Drucker Prager Example

#########################################################

##

# File is generated for the purposes of testing the#

#Drucker-Prager model --> conventional triaxial #

# compression test#

##

# Created: 03.16.2009 CRM#

# Updated: 12.02.2011 CRM#

##

# ---> Basic units used are kN and meters#

##

#########################################################

#-------------------------------------------------------

# create the modelBuilder and build the model

#-------------------------------------------------------

wipe

model BasicBuilder -ndm 3 -ndf 3

#--create the nodes

node 11.00.00.0

node 21.01.00.0

node 3 0.01.00.0

node 40.00.00.0

node 51.00.01.0

node 6 1.01.01.0

node 7 0.01.01.0

node 8 0.00.01.0

#--triaxial test boundary conditions

fix 1 0 1 1

fix 2 0 0 1

fix 31 0 1

fix 4 1 1 1

fix 50 1 0

fix 6 0 0 0

fix 71 0 0

fix 8 1 1 0

#--define material parameters for the model

#---bulk modulus

set k 27777.78

#---shear modulus

set G 9259.26

#---yield stress

set sigY 5.0

#---failure surface and associativity

set rho 0.398

set rhoBar 0.398

#---isotropic hardening

set Kinf 0.0

set Ko 0.0

set delta1 0.0

#---kinematic hardening

set H 0.0

set theta 1.0

#---tension softening

set delta2 0.0

#---mass density

set mDen 1.7

#--material models

# type tag k G sigY rho rhoBar Kinf Ko delta1 delta2 H theta density

nDMaterial DruckerPrager 2 $k $G $sigY $rho $rhoBar $Kinf $Ko $delta1 $delta2 $H $theta $mDen

#--create the element

#type tag nodesmatID bforce1 bforce2 bforce3

element stdBrick 1 1 2 3 4 5 6 7 8 2 0.0 0.0 0.0

puts "model Built..."

#-------------------------------------------------------

# create the recorders

#-------------------------------------------------------

set step 0.1

# record nodal displacements

recorder Node -file displacements1.out -time -dT $step -nodeRange 1 8 -dof 1 2 3 disp

# record the element stress, strain, and state at one of the Gauss points

recorder Element -ele 1 -time -file stress1.out -dT $step material 2 stress

recorder Element -ele 1 -time -file strain1.out -dT $step material 2 strain

recorder Element -ele 1 -time -file state1.out -dT $step material 2 state

puts "recorders set..."

#-------------------------------------------------------

# create the loading

#-------------------------------------------------------

#--pressure magnitude

set p 10.0

set pNode [expr -$p/4]

#--loading object for hydrostatic pressure

pattern Plain 1 {Series -time {0 10 100} -values {0 1 1} -factor 1} {

load 1 $pNode 0.00.0

load 2 $pNode$pNode0.0

load 3 0.0$pNode 0.0

load 5 $pNode 0.00.0

load 6 $pNode$pNode0.0

load 7 0.0$pNode0.0

}

#--loading object deviator stress

pattern Plain 2 {Series -time {0 10 100} -values {0 1 5} -factor 1} {

load 5 0.00.0$pNode

load 6 0.00.0$pNode

load 7 0.00.0$pNode

load 8 0.00.0$pNode

}

#-------------------------------------------------------

# create the analysis

#-------------------------------------------------------

integrator LoadControl 0.1

numberer RCM

system SparseGeneral

constraints Transformation

test NormDispIncr 1e-5 10 1

algorithm Newton

analysis Static

puts "starting the hydrostatic analysis..."

set startT [clock seconds]

analyze 1000

set endT [clock seconds]

puts "triaxial shear application finished..."

puts "loading analysis execution time: [expr $endT-$startT] seconds."

wipe