3.1.10.16. ASDShellQ4 Element

This command is used to construct an ASDShellQ4 element object. The ASDShellQ4 element is a 4-node general purpose thick shell element with the following features:

The membrane behavior is enhanced with the AGQ6-I [ChenEtAl2004] formulation, which makes the element almost insensitive to geometry distortion, as opposed to standard iso-parametric elements.

The drilling DOF is treated with the Hughes-Brezzi [HughesEtAl1989] formulation, with special care to avoid membrane locking, using a 1 point quadrature plus stabilization. This formulation constrains the drilling DOFs to the rigid body rotation via a penalty parameter as a function of the initial in-plane shear modulus. However, when using strain-softening materials, this (elastic) constraint may overstiffen the element as the in-plane shear modulus degrades. As a remedy in such a situation, the user can choose to make this constraint non-linear.

The plate bending part is treated using the MITC4 [DvorkinEtAl1984] [BatheEtAl1985] formulation, to avoid the well known transverse shear locking behavior of thick plate elements.

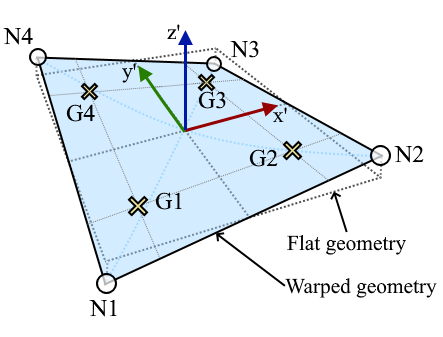

It can be used to model both flat and warped geometries.

Kinematics can be either linear or corotational. The corotational kinematics is based on the work of Felippa et al., i.e. the EICR [Felippa2000] [FelippaEtAl2005] (Element Independent Corotational formulation). Finite rotations are treated with Quaternions.

It uses a full 2x2 Gauss quadrature, so it has a total of 4 integration points.

- element ASDShellQ4 $eleTag $n1 $n2 $n3 $n4 $secTag <-corotational> <-noeas> <-drillingStab $drillingStab> <-drillingNL> <-damp $dampTag> <-local $x1 $x2 $x3>

Argument |

Type |

Description |

|---|---|---|

$eleTag |

integer |

unique integer tag identifying element object |

$n1 $n2 $n3 $n4 |

4 integer |

the four nodes defining the element (-ndm 3 -ndf 6) |

$secTag |

integer |

unique integer tag associated with previously-defined SectionForceDeformation object |

-corotational |

string |

optional flag, if provided, the element uses non-linear kinematics, suitable for large displacement/rotation problems |

-noeas |

string |

optional flag, if provided, the membrane behavior will not be enhanced with the AGQ6-I enhanced assumed strain formulation. |

-drillingStab $drillingStab |

string + float |

optional flag, if provided, the user can specify the stabilization parameter $drillingStab to stabilize the 1-point quadrature drilling DOF formulation (default = 0.01). |

-drillingNL |

string |

optional flag, if provided, the Hughes-Brezzi drilling DOF formulation considers the non-linear behavior of the section. |

-damp $dampTag |

string + integer |

optional, to activate elemental damping as per elementalDamping |

-local $x1 $x2 $x3 |

string + 3 float |

optional, if provided it will be used as the local-x axis of the element (otherwise the default local X will be the direction of the 1-2 side). Note: it will be automatically normalized and projected onto the element plane. It must not be zero or parallel to the shell’s normal vector. |

Fig. 3.1.10.15 Nodes, Gauss points, local coordinate system, warped and flat geometry

Note

Valid queries to the ASDShellQ4 element when creating an ElementRecorder object are:

- ‘force’, ‘forces’, ‘globalForce’, or ‘globalForces’:

Internal forces at the element’s nodes.

Orientation: global coordinate system.

Size: 24 columns of data, 6 components for each one of the 4 nodes.

- ‘material $secTag $secArg1 … $secArgN’:

Section response at section $secTag

$secTag is the 1-based index of the integration point (1 to 4).

‘$secArg1 … $secArgN’ are the arguments required by the SectionDeformationObject at the requested integration point.

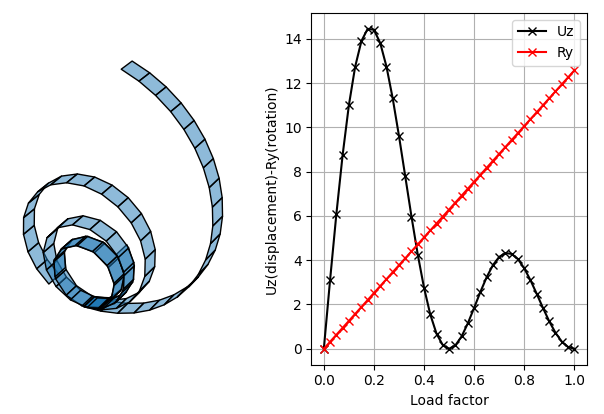

Example 1 - Cantilever Bending Roll-up (corotational)

Example 2

Tcl Code

# set up a 3D-6DOFs model

model Basic -ndm 3 -ndf 6

node 1 0.0 0.0 0.0

node 2 1.0 0.0 0.0

node 3 1.0 1.0 0.0

node 4 0.0 1.0 0.0

# create a fiber shell section with 4 layers of material 1

# each layer has a thickness = 0.025

nDMaterial ElasticIsotropic 1 1000.0 0.2

section LayeredShell 11 4 1 0.025 1 0.025 1 0.025 1 0.025

# create the shell element using the small displacements/rotations assumption

element ASDShellQ4 1 1 2 3 4 11

# or you can use the corotational flag for large displacements/rotations (geometric nonlinearity)

element ASDShellQ4 1 1 2 3 4 11 -corotational

# record global forces at element nodes (24 columns, 6 for each node)

recorder Element -xml force_out.xml -ele 1 force

# record local section forces at gauss point 1 (8 columns: | 3 membrane | 3 bending | 2 transverse shear |)

# note: gauss point index is 1-based

recorder Element -xml force_gp1_out.xml -ele 1 material 1 force

# record local stresses at fiber 1 of gauss point 1 (5 columns: Szz is neglected (0) )

# note: fiber index is 1-based (while in beams it is 0-based!)

recorder Element -xml stress_gp1_fib0_out.xml -ele 1 material 1 fiber 1 stress

Python Code

# set up a 3D-6DOFs model

model('Basic', '-ndm', 3, '-ndf', 6)

node(1, 0.0, 0.0, 0.0)

node(2, 1.0, 0.0, 0.0)

node(3, 1.0, 1.0, 0.0)

node(4, 0.0, 1.0, 0.0)

# create a fiber shell section with 4 layers of material 1

# each layer has a thickness = 0.025

nDMaterial('ElasticIsotropic', 1, 1000.0, 0.2)

section('LayeredShell', 11, 4, 1,0.025, 1,0.025, 1,0.025, 1,0.025)

# create the shell element using the small displacements/rotations assumption

element('ASDShellQ4', 1, 1,2,3,4, 11)

# or you can use the corotational flag for large displacements/rotations (geometric nonlinearity)

# element('ASDShellQ4', 1, 1,2,3,4, 11, '-corotational')

# record global forces at element nodes (24 columns, 6 for each node)

recorder('Element', '-xml', 'force_out.xml', '-ele', 1, 'force')

# record local section forces at gauss point 1 (8 columns: | 3 membrane | 3 bending | 2 transverse shear |)

# note: gauss point index is 1-based

recorder('Element', '-xml', 'force_gp1_out.xml', '-ele', 1, 'material', '1', 'force')

# record local stresses at fiber 1 of gauss point 1 (5 columns: Szz is neglected (0) )

# note: fiber index is 1-based (while in beams it is 0-based!)

recorder('Element', '-xml', 'stress_gp1_fib0_out.xml', '-ele', 1, 'material', '1', 'fiber', '1', 'stress')

Code Developed by: Massimo Petracca at ASDEA Software, Italy.

Chen, Xiao-Ming, et al. “Membrane elements insensitive to distortion using the quadrilateral area coordinate method.” Computers & Structures 82.1 (2004): 35-54. (Link to article)

Hughes, Thomas JR, and F. Brezzi. “On drilling degrees of freedom.” Computer methods in applied mechanics and engineering 72.1 (1989): 105-121. (Link to article)

Dvorkin, Eduardo N., and Klaus-Jurgen Bathe. “A continuum mechanics based four-node shell element for general non-linear analysis.” Engineering computations (1984). (Link to article)

Bathe, Klaus-Jurgen, and Eduardo N. Dvorkin. “A four-node plate bending element based on Mindlin/Reissner plate theory and a mixed interpolation.” International Journal for Numerical Methods in Engineering 21.2 (1985): 367-383. (Link to article)

Felippa, Carlos A. “A systematic approach to the element-independent corotational dynamics of finite elements”. Technical Report CU-CAS-00-03, Center for Aerospace Structures, 2000. (Link to article)

Felippa, Carlos A., and Bjorn Haugen. “A unified formulation of small-strain corotational finite elements: I. Theory.” Computer Methods in Applied Mechanics and Engineering 194.21-24 (2005): 2285-2335. (Link to article)