3.1.5.15. ASDConcrete1D Material

- uniaxialMaterial ASDConcrete1D $tag $E

- <-fc $fc> <-ft $ft>

- <-Te $Te -Ts $Ts <-Td $Td>>

- <-Ce $Ce -Cs $Cs <-Cd $Cd>>

- <-implex> <-implexControl $implexErrorTolerance $implexTimeReductionLimit> <-implexAlpha $alpha>

- <-eta $eta> <-tangent> <-autoRegularization $lch_ref>

Argument |

Type |

Description |

|---|---|---|

$tag |

integer |

Unique tag identifying this material. |

$E |

float |

Mandatory. Young’s modulus. |

-fc $fc |

string + float |

Optional. -fc: A keyword that precedes the float. $fc: The concrete compressive strength. |

-ft $ft |

string + float |

Optional. -ft: A keyword that precedes the float. $ft: The concrete tension (rupture) strength. |

-Te $Te |

string + list |

Optional. -Te: A keyword that precedes the list. $Te: A list of total-strain values for the tensile hardening-softening law. If not specified, $Te will be computed automatically from $fc and $ft. If specified, $Te will override $fc and $ft. |

-Ts $Ts |

string + list |

Optional. -Ts: A keyword that precedes the list. $Ts: A list of stress values for the tensile hardening-softening law. If not specified, $Ts will be computed automatically from $fc and $ft. If specified, $Ts will override $fc and $ft. |

-Td $Td |

string + list |

Optional. -Td: A keyword that precedes the list. $Td: A list of damage values for the tensile hardening-softening law. If not defined, no stiffness degradation will be considered. If not specified, $Td will be computed automatically from $fc and $ft. If specified, $Td will override $fc and $ft. |

-Ce $Ce |

string + list |

Optional. -Ce: A keyword that precedes the list. $Ce: A list of total-strain values for the compressive hardening-softening law. If not specified, $Ce will be computed automatically from $fc and $ft. If specified, $Ce will override $fc and $ft. |

-Cs $Cs |

string + list |

Optional. -Cs: A keyword that precedes the list. $Cs: A list of stress values for the compressive hardening-softening law. If not specified, $Cs will be computed automatically from $fc and $ft. If specified, $Cs will override $fc and $ft. |

-Cd $Cd |

string + list |

Optional. -Cd: A keyword that precedes the list. $Cd: A list of damage values for the compressive hardening-softening law. If not defined, no stiffness degradation will be considered. If not specified, $Cd will be computed automatically from $fc and $ft. If specified, $Cd will override $fc and $ft. |

-implex |

string |

Optional. If defined, the IMPL-EX integration will be used, otherwise the standard implicit integration will be used (default). |

-implexControl $implexErrorTolerance $implexTimeReductionLimit |

string + 2 float |

Optional. -implexControl: Activates the control of the IMPL-EX error. implexErrorTolerance: Relative error tolerance. implexTimeReductionLimit: Minimum allowed relative reduction of the time-step. If the error introduced by the IMPL-EX algorithm is larger than implexErrorTolerance , the material will fail during the computation. The user can therfore use an adaptive time-step to reduce the time-step to keep the error under control. If the reduction of the time-step is smaller than implexTimeReductionLimit , the error control will be skipped. Suggested values: -implexControl 0.05 0.01. |

-implexAlpha $alpha |

string + float |

Optional. Default = 1. The \(\alpha\) coefficient for the explicit extrapolation of the internal variables in the IMPL-EX algorithm. It can range from 0 to 1. |

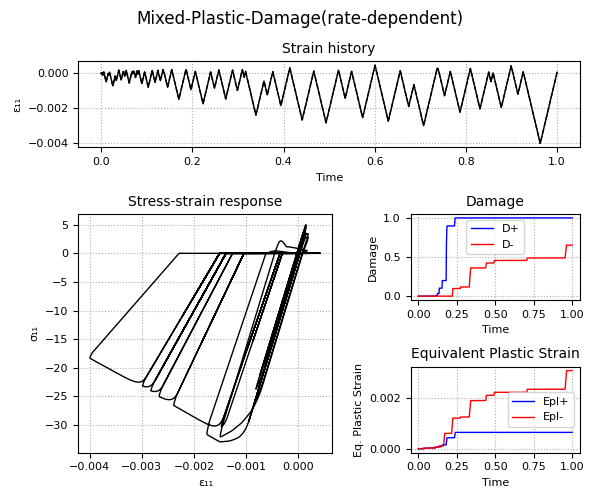

-eta $eta |

string + float |

Optional. If defined, the rate-dependent model is used (By default the model is rate-independent). -eta: Activates the rate-dependent model. eta: The viscosity parameter \(\eta\), representing the relaxation time of the viscoplastic system. |

-tangent |

string |

Optional. If defined, the tangent constitutive matrix is used. By default, the secant stiffness is used. |

-autoRegularization $lch_ref |

string + float |

Optional. If defined, and if the tensile and/or the compressive hardening-softening law has strain-softening, the area under the hardening-softening law is assumed to be a real fracture energy (\(G_f\) with dimension = \(F/L\)), and the specific fracture energy \(g_f\) (with dimension = \(F/L^2\)) is automatically computed as \(g_f=G_f/l_{ch}\), where \(l_{ch}\) is the characteristic length of the Finite Element. In this case $lch_ref is 1. If, instead, the area is a specific fracture energy (\(g_{f,ref}\) with dimension = \(F/L^2\)), $lch_ref should be set equal to the experimental size used to obtain the strain from the displacement jump. In this case, the regularization will be performed as \(g_f=G_f/l_{ch} = g_{f,ref}*l_{ch,ref}/l_{ch}\) |

Note

This is the uniaxial counter-part of the nDMaterial ASDConcrete3D. For the theory, please refer to ASDConcrete3D Material

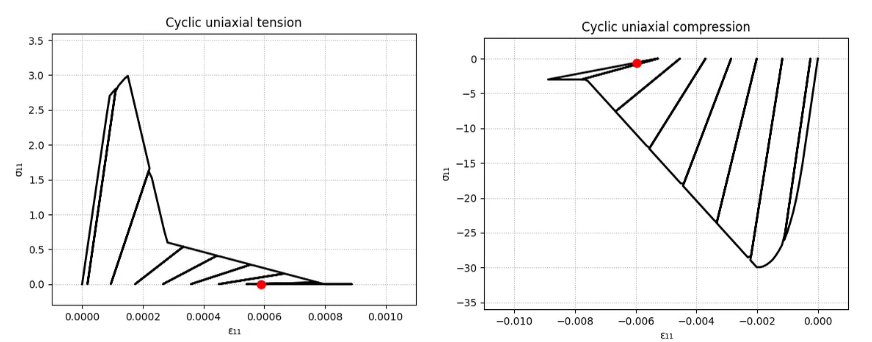

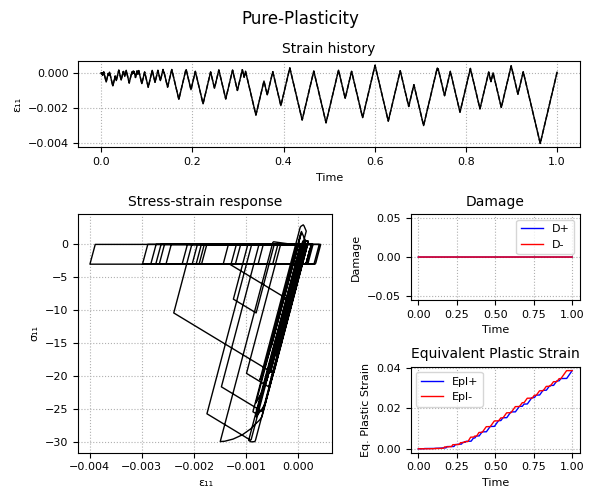

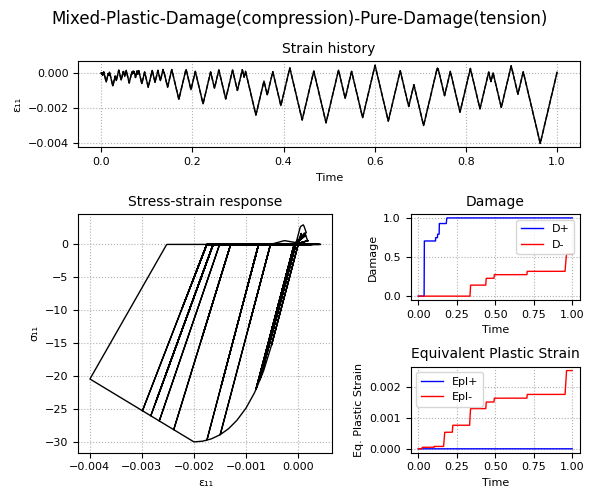

Example 1 - Understanding the Hardening/Softening Laws

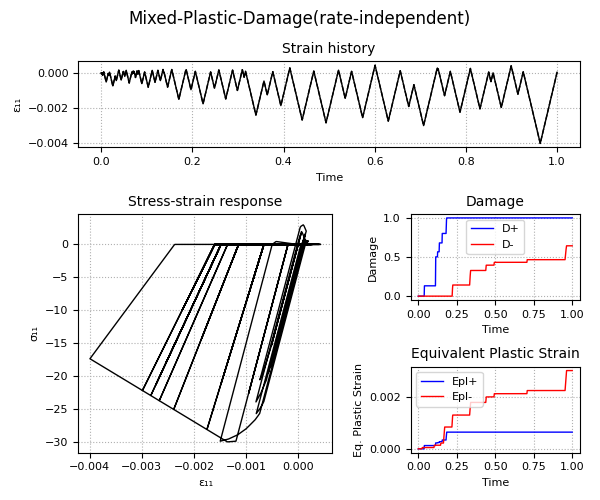

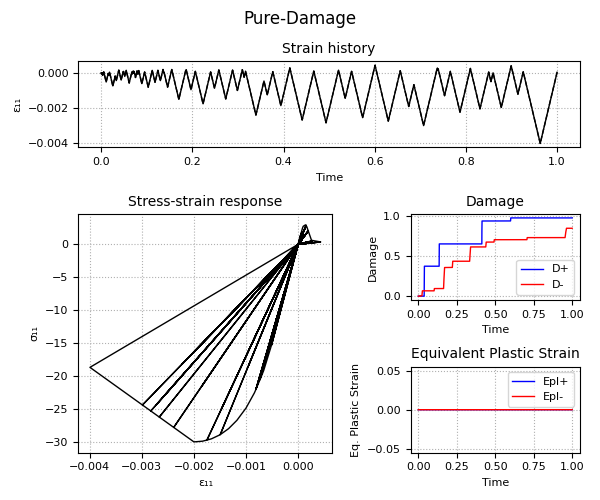

Example 2 - Understanding the Plastic-Damage behavior and the rate-dependent/rate-independent model

Code Developed by: Massimo Petracca at ASDEA Software, Italy.